Close

- Facebook Specials

- New

- Jewelry Presses and Accessories

- Dies & Texture Plates

- Cranston Fancy Wire Co.

- Silver & Copper

- Tools

- Gift Cards

- SALE & CLEARANCE

Menu

- Facebook Specials

- New

- Jewelry Presses and Accessories

- Dies & Texture Plates

- Cranston Fancy Wire Co.

- Silver & Copper

- Tools

- Gift Cards

- SALE & CLEARANCE

- Home Page

- Monthly Subscription Box

- Back

- Monthly Box Bonus Instructions

- Back

- January 2019 Box: Statement Earring Instructions

- September 2020 Box: Hollow Hoop Earrings Instructions

- September 2020 Box Chevron Drop Earrings

- September 2020 Box: How to Solder an Earring Post

- June 2021 Box: Sea Star Impression Die Instructions

- December 2021 Subscription Box Instructions: Chain Links

- September 2022 Box Instructions

- April 2022 Box Vintage Ring Instructions

- April 2024 Monthly Box Postcard

- My Account

- Contact Us

Menu

- Home Page

- Monthly Subscription Box

- Back

- Monthly Box Bonus Instructions

- Back

- January 2019 Box: Statement Earring Instructions

- September 2020 Box: Hollow Hoop Earrings Instructions

- September 2020 Box Chevron Drop Earrings

- September 2020 Box: How to Solder an Earring Post

- June 2021 Box: Sea Star Impression Die Instructions

- December 2021 Subscription Box Instructions: Chain Links

- September 2022 Box Instructions

- April 2022 Box Vintage Ring Instructions

- April 2024 Monthly Box Postcard

- My Account

- Contact Us

(0) items

You have no items in your shopping cart.

All Categories

Popular Products

Rincon Press - Manual - 20-Ton

RIN-MAN

$995.00

Please read the description before purchasing. Named after one of the mountain ranges that surround Potter USA, the Rincon Press is our newest, most compact, and most economical 20-ton jewelry hydraulic press. This press will work with pancake dies, impression dies, silhouette dies, and even our bracelet-forming frame.

$100 Gift Card/Certificate

$100 GC

$100.00

$100 Gift Card. Gift card is a code that will be emailed. No physical card will be mailed. To use the gift card, At checkout, please enter the code in the "Gift Card" code section (not "Discount" code

Rincon Press - Electric - 20-Ton

RIN-ELEC

$3,045.00

Please read the FULL DESCRIPTION below before purchasing. Named after one of the mountain ranges that surround Potter USA, the Rincon Press is our newest, most compact, and most economical jewelry hydraulic press. This press will work with pancake dies, impression dies, silhouette dies, and even our bracelet-forming frame.

Out of stock

Coil Cutter Kit - DREMEL Version

CKit DREMEL

$112.75

This Coil Cutter Kit is for use with a DREMEL only. See below for specifics. Kit includes: Aluminum 6" long coil holder block and steel top plate for holder; Saw blade, guard for Dremel with adapter bushing, 1 saw arbor to fit 3/8" hole blades. Coils to be cut can be up to 4 inches long and 7/8 inch (22 mm) in outside diameter. Coils may be made of 14 through 30 gauge wire. (Coils of 30g wire can not be smaller than 1/8" inner diameter.) (NOTE: Does not fit battery-powered, cordless or very old Dremels). We use a Dremel 200 here in our shop.

Out of stock

Bracelet Forming Kit with Frame

BF Kit

$532.75

Now for bangles too! NEW bracelet forming frame, 2" 95 durometer urethane puck, and set of 4 formers. Please read the information below. Beam: 6"L x 3/4"H Columns: 2 1/2"H x 1 5/8"W (top), 2"W (bottom) Large Synclastic former: 2 7/16"W x 1 3/4"H Small Synclastic former: 1 7/8"W x 1 11/16"H Large Anticlastic former: 2 15/16"W x 1 3/4"H Small Anticlastic former: 1 15/16"W x 1 11/16"H

Rincon Press LAYAWAY

Rincon Press LAYAWAY

$100.00

This option is for LAYAWAY Payment for the NEW Rincon Press. Manual: $995 Electric: $3,045 This is our newest, most compact, and most economical 20-ton jewelry hydraulic press. This press will work with pancake dies, impression dies, silhouette dies, and even our bracelet-forming frame.

Aluminum Spacer (4.5” x 7.75” x 1”)

Al-Spacer

$34.75

This spacer is 4.5'' x 7.75'' and 1'' thick. Non magnetic Spacers are used in the press to lessen the amount of effort needed to extend the jack and activate the items being used in the press. Top and bottom platens are not meant to touch - it will cause the jack to overextend and cause leaking, or for jack to fail. Always use spacers on lower platen to take up space between platens.

20 Ton Electric Press UPGRADE

20 ton electric upgrade

$2,095.00

This is just the electrical upgrade parts - **FRAME NOT INCLUDED**. This system consists of a 20 ton electric hydraulic pump and cylinder. This allows for faster cycling. No more hand pumping the jack! Great for those who are looking to increase their productivity or are just tired of pumping a jack. Freight shipping up to $250. Any additional fees - delivery to rural area, busy city fee, indoor delivery or other additional fees will be invoiced to you. **ANY INVOICES FOR ADDITONAL FREIGHT SHIPPING WILL BE SENT THE DAY OF SHIPMENT.** ***Be sure you have a most current phone number on record. We will give you a call between the hours of 9am-5pm MTS(AZ) to confirm both address and phone number for the freight company.***

Out of stock

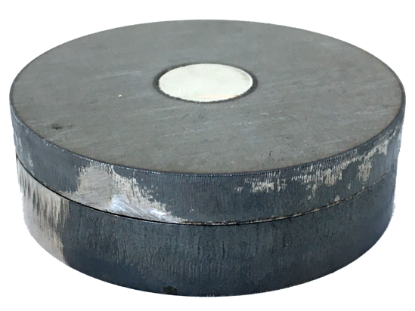

2 x 2 Contained Urethane with Pusher

2 x 2 Contained Urethane

$62.75

2" x 2" contained urethane with pusher for use with our standard, 2" silhouette dies. Kit includes: container, 95 durometer urethane, metal pusher (silhouette dies sold separately). NOT for use with impression dies.

Out of stock

New Products

Impression Die French Flowers Quintet

VM-SP781-ABCDE

$70.00

Get five gorgeous, late-1900s French flower dies on a single puck! Each image is 9-9.5mm diameter.

Quick-Form Press Angle Forming Set

QF-ANGLSET

$85.00

Two delrin conforming formers in 90° and 60° angles, and a corresponding steel angle forming mandrel. Use ONLY with the Quick-Form Press, Former Adapter, and Flat Bracelet Formers. The conformers must mount on the Former Adapter (sold separately).

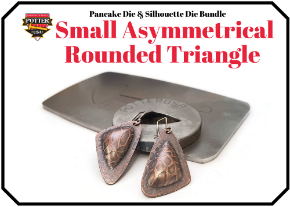

Silhouette Die Teardrop

SD193

$21.40

Silhouette die dimensions: 1-1/8" x 11/16". Overall die dimensions - 1-15/16" diameter.

Pancake Die PD 1822 Fold Over Trillion Pendant

PD 1822

$30.50

Design: 2-3/8" x 13/16". Die: 5" x 4-3/8".

Pancake Die 1824 - 3.5" Spoon Shape A

PD 1824

$55.00

Design: 3-1/2" x 2-11/16" Die itself: 7" x 4-1/2" Coordinated to work with the 3" Spoon Shape B Dish Former Silhouette Die (DF-033). ***Will not fit in the discontinued Potter USA medium press***

Pancake Die 1823 - 3.5" Spoon Shape B

PD 1823

$55.00

Design: 3-1/2" x 2-3/8" Die itself: 7" x 4-3/8" Coordinated to work with the 3" Spoon Shape B Dish Former Silhouette Die (DF-034). ***Will not fit in the discontinued Potter USA medium press***

Dish Former Silhouette Die - 3" Spoon Shape B

SD-DF-034

$40.00

Brand new! Use this tool to make shallow domed forms, such as trinket dishes, lockets, small containers, etc. 3" wide x 1-7/8"" tall, 1/4" thick. Must be used with a large sheet of urethane (available separately). ***Will not fit in the discontinued Potter USA medium press***

Silhouette Die Spoon Shapes C

SD322

$55.00

Silhouette Die Dimensions (from largest shape to smallest): 1-1/2" x 15/16", 1-3/8" x 7/8", 1" x 11/16" 3/4" x 1/2" Overall Die Dimensions: 3-7/8" x 3-15/16" These shapes make excellent spoon bowls!

Menu

Shopping cart

Filters

Personal menu

Preferences

Search

Latest From Blog

9/28/2023 12:00:00 AM 3

Collection Spotlight: the Parisi Tool & Die Company

PotterUSA celebrates the first major tool & die company Kevin Potter ever bought....

3/21/2021 5:00:00 PM 2

Cranston Fancy Wire Company

In 2018, Kevin and Vincent Potter travelled to Providence, RI in search of antique jewelry dies, and found the Cranston Fancy Wire Company. The company was with its second owner, who had to close the ...

3/21/2021 5:00:00 PM 3

Hidden Histories: Peter DiCristofaro and the Providence Jewelry Museum

If the history of American jewelry making rests upon anyone’s shoulders, it is Peter DiCristofaro’s.

As curator and caretaker of the Providence Jewelry Museum in Rhode Island, the first museum in the...

3/21/2021 5:00:00 PM 3

The Life and Death of the Frank Morrow Company

Only a spare few metalworking companies survived the epic decline of the industry between the late 20th century to early 21st century.

The epitome of historic American toolmaking giants, ...

Information

Customer service

My account

Contact Us

- 1934 E. 18th Street, Tucson, AZ 85719

- [email protected]

- 520.777.6032

Copyright © 2024 Potter USA. All rights reserved.

.png)

(1200 × 500 px).png)

.png)

.png)

(1).png)